Production Capacity

Our production is 100,000pcs a year. And order from the combi freezer has many people who usually come from Southeast Asia. Other styles, such as upright, chest, island, and countertop display freezers, are also produced.

Quality First

Quality is Xuefumei’s first step in production. Bad quality will affect the brand and reduce customer repurchase. With many years of experience in the freezer industry, we meticulously implement quality control, down to the smallest detail, to ensure that pre-shipment inspections meet our standards. Workers inspect products several times before shipment, confirming they are free of defects before shipping them to the warehouse.

Core Component - Copper Tubing

Our freezers are equipped with copper pipes to facilitate heat conduction, ensuring rapid refrigerant flow and optimal cooling performance. Copper pipes are also corrosion-resistant, ensuring the freezer maintains its cooling performance for years.

Sheet Metal Cutting – Laser Cutting

The fan housing at the bottom of the freezer is hollowed out. This hollowing is laser-cut, ensuring each hole is precisely sized and positioned. Automatically controlled by the machine, this further reduces production time.

Heat Dissipation Components – Evaporator fan unit

The freezer evaporator fan assembly frame is an aluminum bracket that secures the entire evaporator module. The fan, mounted on the bracket, provides forced air circulation. The entire assembly is placed inside the freezer to circulate the cooled air.

Quality Control – Testing Room

After completing all the steps, workers place the freezers in a testing room for various environmental tests. Only after they pass repeated inspections will the finished products be shipped to the warehouse. Data from each freezer test is recorded, and any issues identified are corrected.

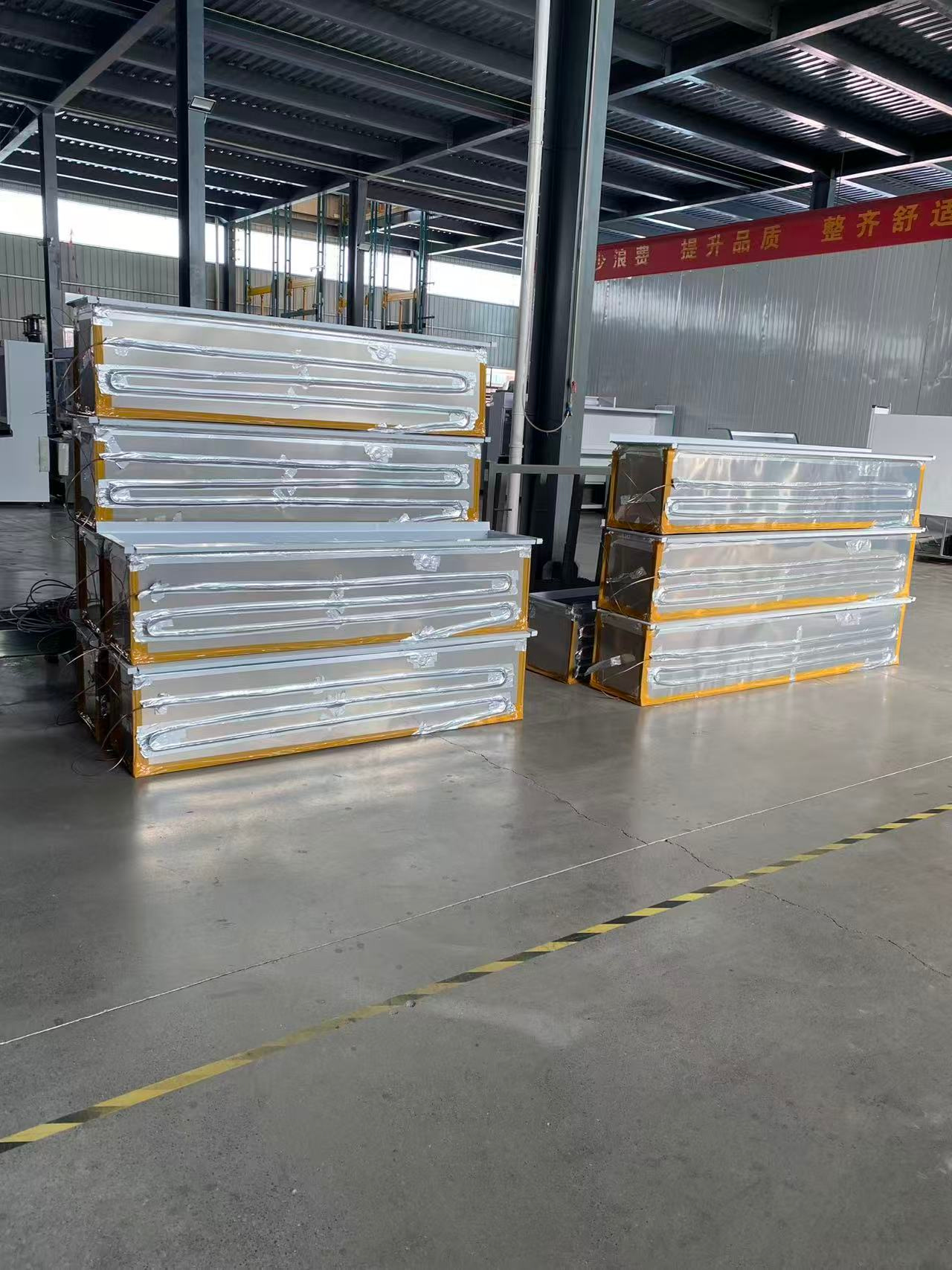

Safe Transport - Professional Packaging

Many unpredictable situations arise during transportation, especially since our freezers are large and prone to damage. To prevent this, we use protective film and wooden frames for packaging. This ensures that customers receive their freezers in good condition, no matter how far they travel.

Step Inside Xuefumei

Entering the Xuefumei factory, every detail is meticulously detailed. Workers inspect semi-finished freezers, others are busy assembling glass, and even more are assembling the insulation and exterior of the cabinets. Finished freezers are neatly displayed in our warehouse. With meticulous attention to detail, we strive to achieve even greater success in the field of freezers.

- Display